Engineering is an ever-evolving discipline that thrives on innovation and problem-solving. It encompasses a wide range of industries and applications, from building bridges and skyscrapers to developing cutting-edge technologies. At the heart of engineering lies the pursuit of efficient and effective solutions to complex challenges.

This article explores the essence of engineering, focusing on the importance of innovation and problem-solving. As technology continues to advance, engineers are at the forefront of creating new possibilities and pushing the boundaries of what is possible.

One vital aspect of engineering is steel fabrication services, which play a pivotal role in various construction and manufacturing projects. Let us delve into the world of engineering, where creativity meets practicality, and explore the fascinating subheading of steel fabrication services.

Contents

- 1 The Significance of Steel Fabrication

- 2 Techniques and Processes in Steel Fabrication

- 3 Applications of Steel Fabrication Services

- 4 Quality Assurance and Compliance in Steel Fabrication

- 5 Advancements in Steel Fabrication Technology

- 6 The Role of Automation in Steel Fabrication

- 7 Challenges and Future Trends in Steel Fabrication

The Significance of Steel Fabrication

Steel fabrication plays a pivotal role in the field of engineering, offering a multitude of advantages and opportunities for various industries. One of the key reasons for the significance of steel fabrication is its exceptional strength and durability. Steel is renowned for its robustness, making it an ideal material for constructing bridges, buildings, and infrastructure that can withstand extreme conditions and heavy loads.

Moreover, steel fabrication allows for versatility in design, enabling engineers to create intricate structures and components tailored to specific project requirements. Additionally, steel fabrication offers cost-effectiveness due to its longevity and low maintenance needs. The ability to fabricate steel into complex shapes and sizes further enhances its usability across a wide range of applications. With its numerous advantages, steel fabrication remains a cornerstone of engineering, shaping the modern world.

Techniques and Processes in Steel Fabrication

Steel fabrication encompasses a range of techniques and processes that transform raw steel into finished products. Welding, a widely used method, involves joining steel pieces by melting them together, creating a strong and cohesive bond. As per professionals from Hitec Welding, another essential process is cutting, which utilizes various methods like laser cutting, plasma cutting, or sawing to shape steel according to design specifications.

Forming, bending, and rolling techniques shape the steel into desired angles and curves. Additionally, drilling, punching, and machining are employed for creating holes, slots, and precise details. Surface treatment techniques such as grinding, sandblasting, and painting are utilized to enhance the appearance and protect against corrosion.

Applications of Steel Fabrication Services

Steel fabrication services find extensive applications in numerous industries, contributing to the development of infrastructure, manufacturing, and transportation sectors. In the construction industry, steel fabrication is indispensable for erecting high-rise buildings, bridges, stadiums, and industrial structures. Its strength and versatility allow architects and engineers to create innovative designs, pushing the boundaries of modern architecture. Moreover, steel fabrication is vital in the manufacturing sector, where it is used to produce machinery, equipment, and components for various industries, including automotive, aerospace, and energy.

The transportation industry relies on steel fabrication for manufacturing ships, trains, automobiles, and aircraft components. Steel fabrication also plays a crucial role in the renewable energy sector, supporting the construction of wind turbines and solar panel frameworks. The widespread applications of steel fabrication services underscore its importance and contribution to advancing numerous sectors of the economy.

Quality Assurance and Compliance in Steel Fabrication

Ensuring quality and compliance is paramount in steel fabrication to guarantee the reliability and safety of fabricated steel products. Quality assurance begins with rigorous inspections and testing of raw materials to verify their compliance with industry standards. Throughout the fabrication process, strict quality control measures are implemented to monitor and maintain the integrity of the fabricated steel components. This includes dimensional checks, visual inspections, non-destructive testing, sheet resistance measurement instrument applications to assess material conductivity, and material traceability.

Compliance with relevant codes and regulations is also crucial to meet safety standards and legal requirements. Certifications such as ISO 9001 and AWS (American Welding Society) ensure that the steel fabrication process adheres to established quality management systems.

Incorporating advanced tools like a sheet resistance measurement instrument can enhance precision during the testing phase, supporting higher compliance with stringent quality requirements. By prioritizing quality assurance and compliance, steel fabrication services instill confidence in the end users and contribute to the overall success and longevity of engineering projects.

Advancements in Steel Fabrication Technology

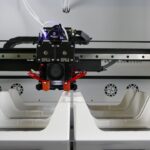

Steel fabrication has undergone significant advancements in technology, revolutionizing the efficiency, precision, and capabilities of the process. Computer-Aided Design (CAD) software enables engineers to create intricate 3D models of steel structures, streamlining the design phase and facilitating accurate visualization. Computer Numerical Control (CNC) machines have transformed steel fabrication by automating processes such as cutting, drilling, and milling, enhancing precision and reducing human error. Robotic welding systems provide consistent and high-quality welds, improving efficiency and productivity.

Advanced laser and plasma cutting technologies offer faster and more precise cutting capabilities, enabling intricate designs and reducing material waste. Moreover, the integration of digital connectivity, the Internet of Things (IoT), and data analytics allows for real-time monitoring, predictive maintenance, and optimization of steel fabrication operations. These technological advancements empower engineers and fabricators to push the boundaries of what is achievable in steel fabrication, driving innovation and efficiency.

The Role of Automation in Steel Fabrication

Automation has emerged as a game-changer in steel fabrication, revolutionizing productivity, accuracy, and overall efficiency. Automated systems and robotics have minimized the need for manual labor and accelerated production cycles. CNC machines, robotic arms, and material handling systems work seamlessly together, reducing human error and maximizing output. Furthermore, automation has improved workplace safety by eliminating hazardous tasks and reducing the risk of accidents.

By utilizing sensors and advanced control systems, automation ensures precise material handling, cutting, and welding, resulting in consistent quality. The integration of automation also enables seamless data exchange, allowing real-time monitoring and optimization of processes. With the ability to operate 24/7, automated steel fabrication facilities enhance productivity and shorten project timelines.

Challenges and Future Trends in Steel Fabrication

Steel fabrication, like any other industry, faces a set of challenges that prompt the need for continuous improvement and adaptation. One such challenge is the rising cost of raw materials, as fluctuations in steel prices impact project budgets and profitability.

Additionally, skilled labor shortages pose a hurdle, as experienced fabricators and welders become increasingly scarce. Environmental concerns and sustainability considerations also drive the need for eco-friendly practices in steel fabrication, promoting the exploration of greener materials and processes.

Looking ahead, future trends in steel fabrication involve the integration of advanced technologies such as additive manufacturing (3D printing) for intricate steel components, the use of sustainable materials like recycled steel, and the implementation of digital twin technology for enhanced project planning and simulation.

Engineering epitomizes innovation and problem-solving, driving progress across numerous sectors. Through constant advancements and adaptability, engineers are revolutionizing the world we live in. Steel fabrication services serve as a prime example of engineering excellence, enabling the construction of robust structures and the creation of intricate components.

With various techniques, processes, and cutting-edge technology, steel fabrication has become more efficient and precise. Quality assurance and compliance ensure the durability and safety of fabricated steel products, while automation streamlines production and enhances productivity. However, challenges persist, and future trends in steel fabrication aim to address them, such as the integration of sustainable practices and the exploration of new materials.